Special Projects

Caprock Integrity Study for Thermal Recovery Projects

Caprock Integrity Study For Thermal Recovery Projects

BGES has developed a comprehensive and proprietary process to assess caprock integrity in thermal recovery projects including steam assisted gravity drainage (SAGD) and cyclic steam stimulation (CSS). These processes involve the injection of steam into the reservoir at high pressure and high temperature in order to mobilize the bitumen. Rock layers above, known as the caprocks, must display sufficient hydraulic and mechanical integrity to withstand injection pressures in an in-situ production. However, continuous or cyclic injections can lead to changes that alter in-situ stress states, reduce rock strength, initiates or re-open fractures, etc. Inability of the caprock to contain the steam and hydrocarbons may allow them to escape to shallower units and even the surface.

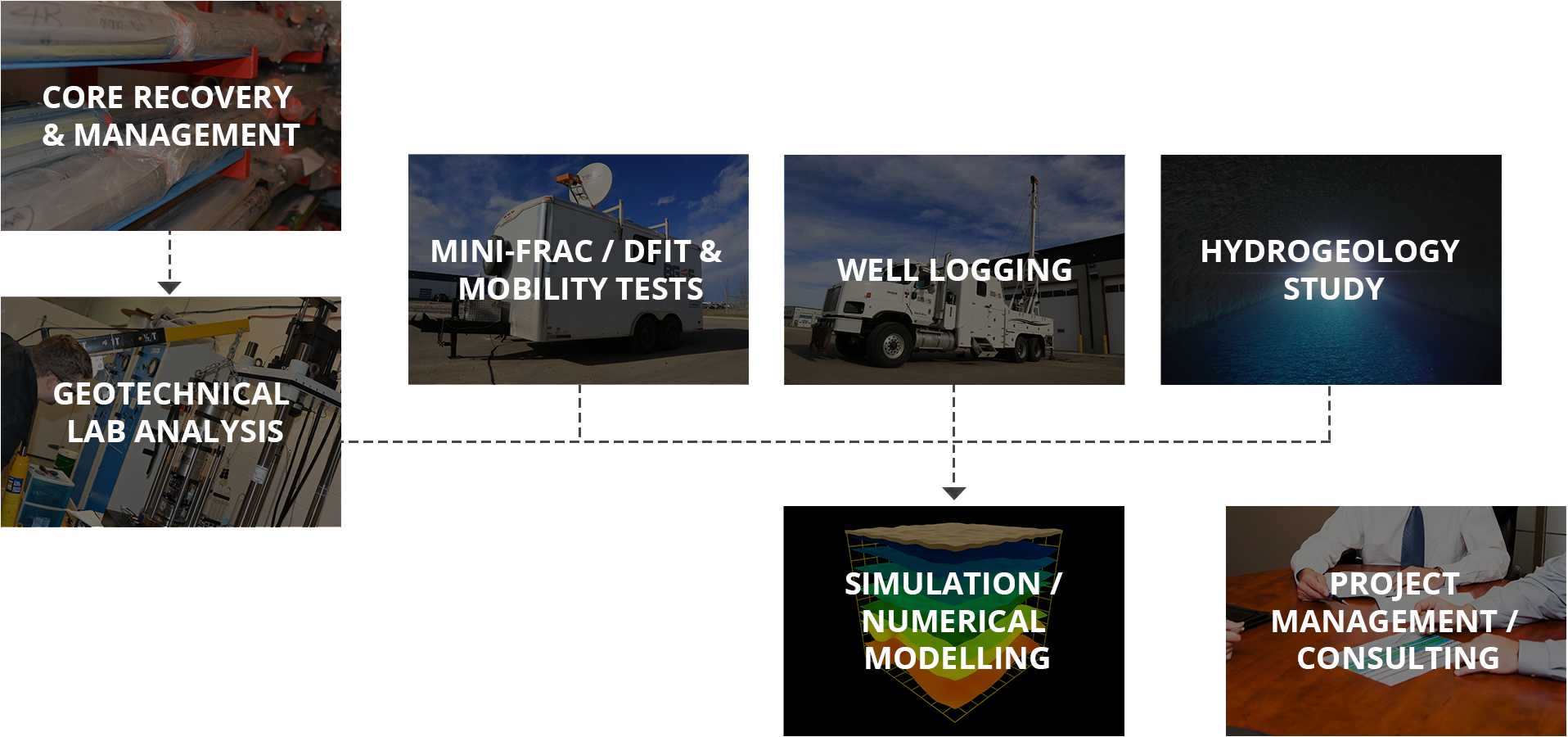

To mitigate risks of caprock failure, we use the following suite of assessments, based on geomechanics principles, to gain an in-depth understanding of possible failure mechanisms and to predict potential effects of thermal production on the in-situ conditions.

Caprock core testing for rock properties (including permeability) and strength

Cased-hole logging to assess hydraulic isolation and wellbore integrity

Static pressure measurement to obtain pore pressure

Coupled reservoir-geomechanics modelling to simulate operation and predict changes in in-situ conditions

What People Say

“Caprock containment is not only critical for the economic success of these projects but also ensures safety and environmental protection. The Big Guns process has been proven to work and has received international recognition. Their process is considered to be a critical factor in the future success of in-situ recovery projects.”