Oil Sands

GeoContainment™ Evaluation

For Oil Sands & Heavy Oil Enhanced Recovery

What is GeoContainment™ ?

GeoContainment is critical to the success and safety of enhanced oil recovery schemes such as Steam Assisted Gravity Drainage (SAGD), Cyclic Steam Stimulation (CSS), waterflood and solvent-based enhance oil recovery processes. Such processes involve the injection of steam or other fluids into the reservoir at high pressure (and potentially high temperature) in order to mobilize the heavy oil/bitumen. Rock layers directly above these types of reservoirs, known as the caprock, is a non-permeable formation acting as a seal. In order to control the mobility of steam, bitumen, waste or formation fluid, the caprock must display sufficient hydraulic and mechanical integrity to withstand injection pressures in an in-situ production. Evaluation of the underburden seal is also important in some applications to ensure complete GeoContainment. In recent years the number of caprock failures in the oil sands has made subsurface GeoContainment critical for public safety and environmental protection.

Please refer to the Caprock Integrity Study page for an example of how BGES can help.

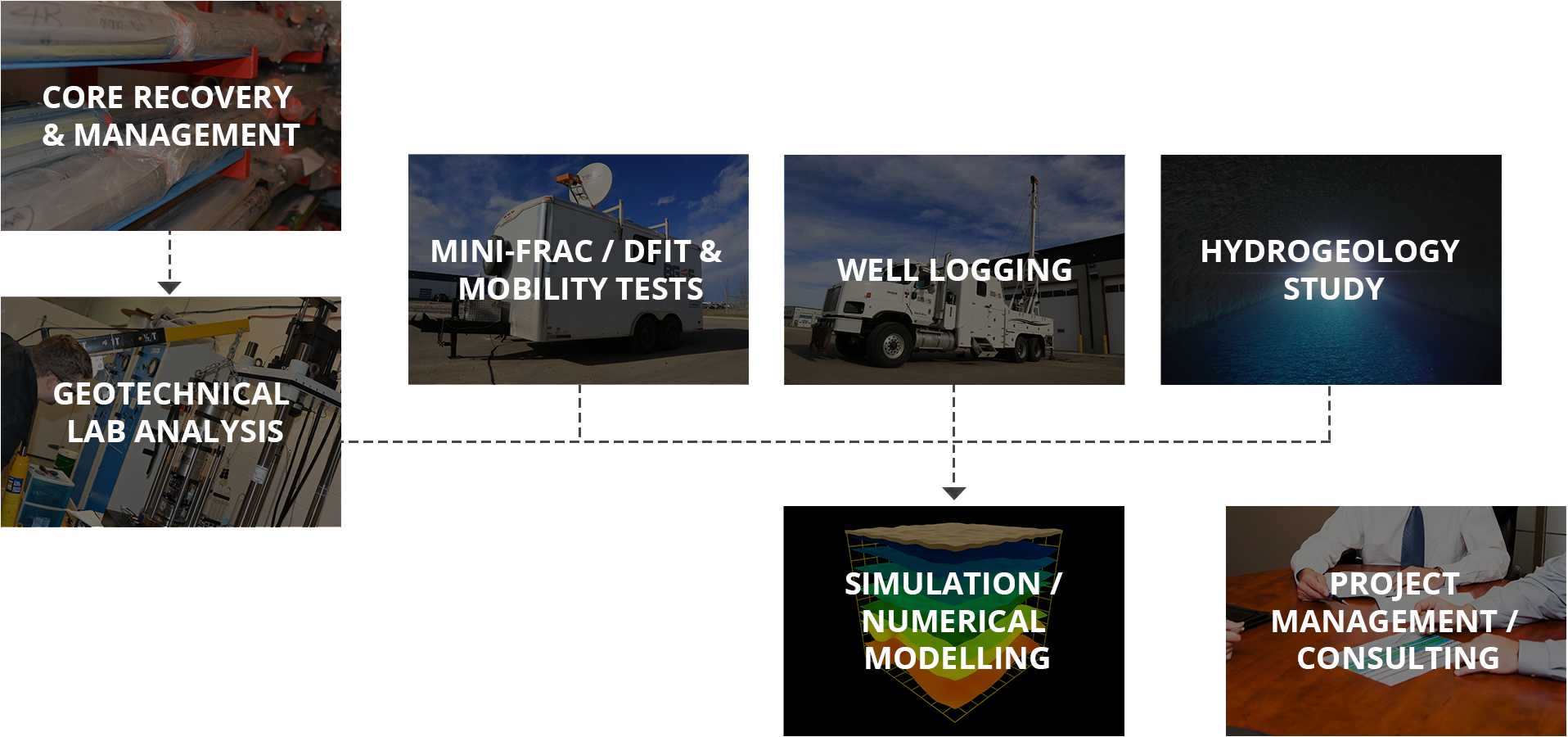

Integration of Services

Core Preservation and Management

Once the caprock cores arrive at our geotechnical lab, BGES ensures diligent preservation and management to maintain their integrity. We handle the cores with extreme care, immediately placing them in a controlled environment to preserve the original rock properties. This crucial step ensures that subsequent testing reflects the true characteristics of the caprock in the reservoir. After safe transport to our lab in Calgary, the cores undergo further processing and detailed analysis by our experienced technical professionals, ensuring high-quality results and reliable data for caprock evaluation.

Geotechnical Laboratory with High-Temp Triaxial Analysis

Triaxial tests generate essential inputs for caprock modelling and are therefore necessary to determine caprock integrity in thermal operations. BGES specializes in testing caprock core for steam-assisted gravity drainage (SAGD) and cyclic steam stimulation (CSS) applications. The company has developed proprietary processes for acquiring, storing, transporting and testing caprock samples, and is home to one of the few high-temp full core triaxial testing apparatus in Calgary. Our deliverable includes a detailed analysis on lab results completed by highly-qualified technical professionals.

Mini-Frac / DFIT

BGES’ analysis approach provides consistent interpretation using a combination of diagnostic tools to give the most dependable results. A comprehensive analysis and interpretation of results is conducted by experienced technical professionals.

Step Rate Test (SRT)

BGES utilizes a test simulator along with a multi-stage method to carefully design the injection schedule. We are experienced in designing and successfully executing SRT’s to satisfy regulatory requirements.

Water Mobility Test

Surface & Downhole Data Acquisition

Cased-Hole Logging

Production Optimization

Hydrogeology Study / Analysis

Hydrogeology studies are essential for oil sands projects, particularly in understanding the reservoir fluid’s hydrochemistry and properties, which play a critical role in reservoir modeling. The characteristics of groundwater, such as its flow, composition, and interaction with reservoir fluids, impact the overall dynamics of the reservoir. BGES offers comprehensive hydrogeology services, focusing on the characterization, assessment, and modeling of groundwater sources and movement within oil sands reservoirs.

Project Management & Consulting