Carbon Capture, Utilization & Storage (CCUS)

GeoContainment™ Evaluation

For Subsurface or Geologic Carbon Sequestration Projects

What is GeoContainment™ ?

In the pursuit of reducing global climate change, carbon capture, utilization, and storage (CCUS) have emerged as vital priorities worldwide. Carbon capture and storage (CCS) is the efficient process of securely storing carbon dioxide (CO2) in underground geologic formations. Through pressurization, CO2 transforms into a liquid state, ready for injection into porous rock formations, depleted oil and gas reservoirs, saline aquifers, or bedded rock salt caverns. The success of CCUS is dependent on the reliable containment of injected CO2 within the designated storage site.

To ensure effective CO2 containment, the caprock’s seal potential is crucial. The rock layers overlying the storage formation must exhibit strength, integrity, and continuity to avoid seepage or migration of the stored carbon. BGES specializes in a comprehensive suite of services that streamline AER Directive 51 application and ensure the safety and efficiency of CCUS operations. Trust our expertise to facilitate your carbon capture and storage initiatives while adhering to regulatory requirements and industry best practices.

For carbon storage in underground caverns, we offer a full suite of technical services for the entire lifecycle of the cavern. Please refer to the Storage Cavern page for more details.

Cased-Hole Logging

With over 23 years of experience in wireline services, BGES excels in a comprehensive range of specialized cased-hole logging solutions. Our expertise in disposal wells and AER Directive 51 application includes casing inspection logs, cement bond logs, and multi-temp profiling. Count on our dedicated team to handle complex wireline projects in even the most challenging environments. Experience the difference of working with a highly skilled wireline service provider committed to delivering exceptional results.

Spinner Survey

Spinner surveys play a vital role in carbon disposal wells/formations, aiding in the evaluation of fluid behavior and optimizing carbon storage operations. Multiple passes are performed at different tool and fluid velocities to generate a comprehensive flow profile. BGES provides skilled interpretation of the collected data to assess flow velocities, identify preferential flow areas, and detect potential anomalies or restrictions. This in turn enables clients to make important decisions on production optimization, well integrity, and disposal management. Utilizing spinner surveys in carbon disposal zones maximizes storage efficiency and minimizes risk of migration.

Mini-Frac / DFIT

Mini-frac (or DFIT) is one of the most common and reliable techniques for indirectly measuring a formation’s minimum in-situ stress, which is a critical parameter for determining safe injection pressure and caprock integrity. BGES’ analysis approach provides consistent interpretation using a combination of diagnostic tools to give the most dependable results. A comprehensive analysis and interpretation of results is conducted by experienced technical professionals.

Step Rate Test (SRT)

Step-rate injectivity test has been a proven method for effectively determining the formation parting pressure (or FPP). AER’s Directive 51 relies on this pressure to establish the maximum injection pressure in injection/disposal wells. The success of an SRT hinges on factors such as the initial injection rate, precise time steps, and rate increments. At BGES, our expertise lies in utilizing a test simulator and employing a meticulous multi-stage approach to design the optimal injection schedule. We are highly experienced in designing and successfully executing SRTs to satisfy regulatory requirements.

Core Recovery and Management

Reliable caprock integrity evaluation begins with a diligent caprock core handling and management process. BGES provides end-to-end caprock core solutions, beginning with specialized handlers and a mobile facility managed by an experience technical professional at the wellsite. After careful cutting and preserving on location, the caprock core is transported, using a specially-designed and environmentally-controlled trailer, to our geotechnical lab in Calgary for further processing.

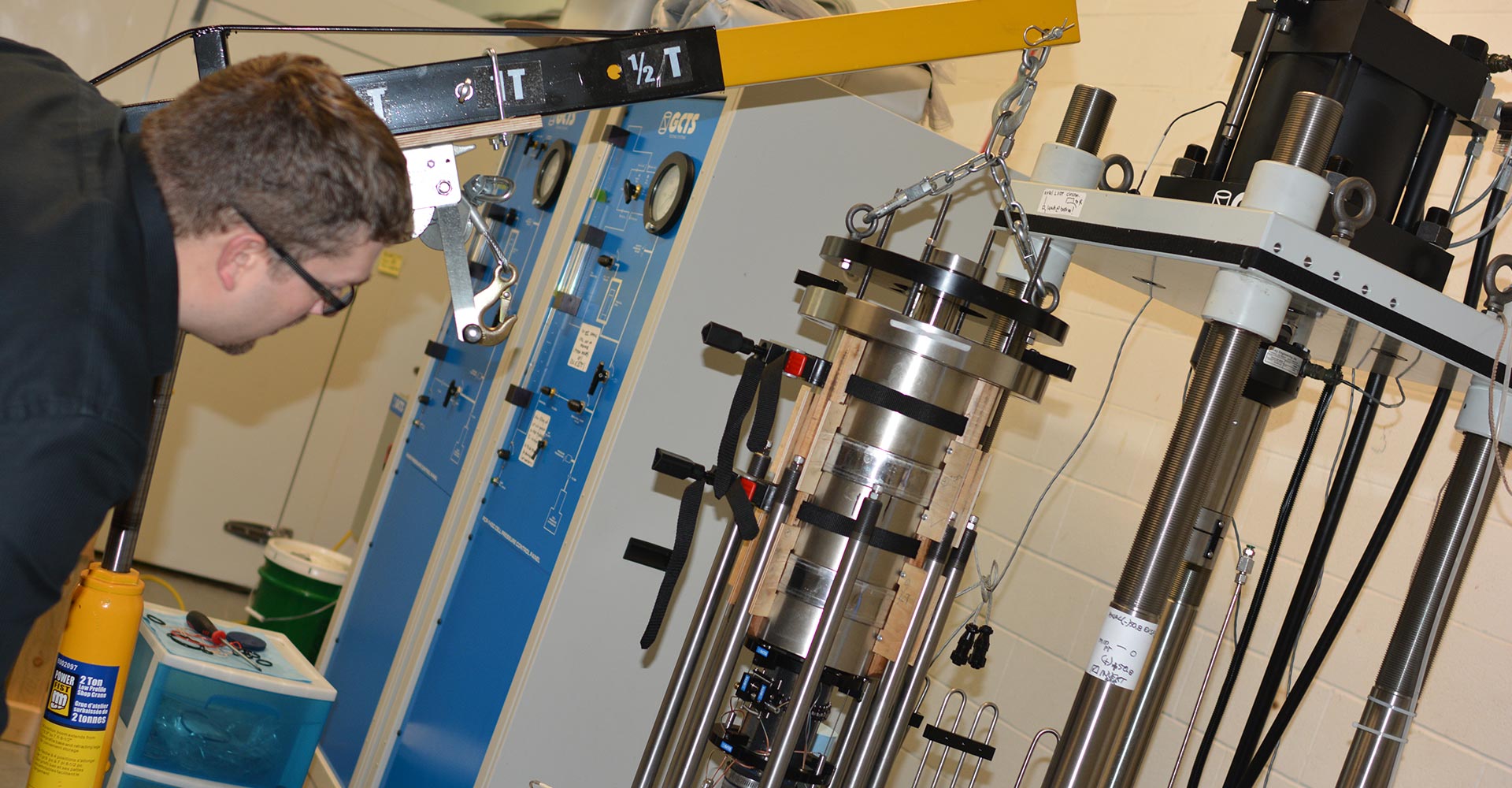

Geotechnical Lab Testing (Triaxial Analysis)

Triaxial tests generate essential data including rock strength for determining caprock integrity in CCUS projects. BGES has developed proprietary processes for acquiring, storing, transporting and testing caprock samples. Our deliverable includes a detailed analysis on lab results completed by highly-qualified technical professionals.

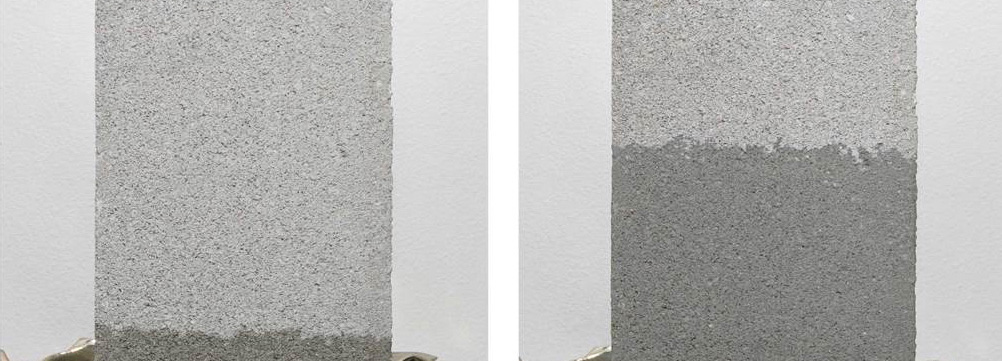

CO2 Permeability Test

Understanding the caprock’s permeability to CO2 can help predict the movement of the stored carbon. Caprock permeability refers to the measure of a caprock’s ability to allow fluid flow, influencing the potential for fluid migration and the effectiveness of containment. In addition to the standard triaxial tests, lab permeability testing is also important to assess the caprock’s sealing capability.

Capillary Breakthrough Test

The effectiveness of the caprock as a barrier or upper seal also relies on the interfacial tension within the interconnected network of pores in low-permeability caprocks. Capillary pressure, or the interfacial tension, plays a critical role in preventing the ingress of stored fluids (such as carbon) into the caprock. The caprock capillary breakthrough test is designed to assess the point at which capillary forces are overcome, leading to fluid movement into and across the caprock formation.